25mm Seamless Neck Banger

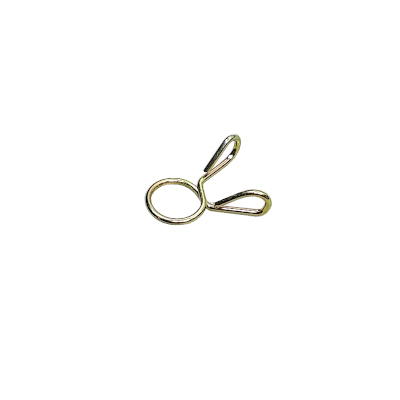

The 25mm fully worked banger features seamless welds for a sturdy, unified construction and increased strength. It includes a clamp to secure the coil onto the bottom of the banger for the perfect fit.

Features:

- 25mm outer diameter

- Fully worked, seamless welds

- 14mm male joint to rig size

- Clear bottom

- Clamp for holding your heat coil to the bottom of the banger

The heat coil is not included. They are available here.

$28.99

Why Is 25mm The Standard Size For Bangers?

25mm is the most popular choice for banger size. Most people avoid anything larger because it just seems like overkill for most dabbers who prefer smaller to moderate portions and don’t tend to glob out on monster dabs. For those who leave their set on all day, a larger coil also means a slightly higher electricity bill at the end of the month. A 25mm banger is the best mix between energy bills and efficiency. It just doesn’t make as much sense for most people to go with any larger unless they have concerns about efficiency with large dabs and also have a larger rig to support the extra bulk. This ensures the rig always stays upright and the carpet always stays dry (and un-burnt).

Clamp Holder Safety

A hose clamp is the most secure option to hold your banger up to your heat coil. Other options such as the bands are also can work well, but may not hold well with bangers that have a certain neck shape. If the neck is too sloped the coil will tend to tilt quite a bit, losing a lot on heat transfer efficiency. The clamp below the bucket ensures that you always have a fairly tight fit between the coil and the bottom of your banger bucket.

Slippage With Other Solutions

Other solutions such as bands or ties may slip down over time. This sometimes results in a larger than optimal gap between the banger and coil, resulting in reduced heat transfer. The bottom of the heat coil must be as close as possible to the bottom of the bucket for maximum transfer efficiency.

Conner Goertzen

I am a DIY electronics enthusiast who has been 3D printing since 2018, making custom e-nail controllers since 2016, and putting together custom electronic instruments since 2011.