How to Choose The Right Dab Surface

Going from flower to dabbing concentrates can feel like you’re moving to a whole new country. You go from the relatively primitive technique of rolling a joint and setting it on fire like a caveman, to discovering the wide open world of dab rigs, bangers, slurpers, pearls, and more. If you’ve reached this point you may be confused about the different options and wondering if your setup is up to par with some of the latest gadgets and upgrades for your dab station.

If you are just curious or are on a quest for the latest and greatest, here is a list of all the ways in which a dabber may modify their dab surface to maximize the desired flavor and effect. We’ll look at the main factors that go into choosing accessories that modify your dab surface for optimal performance. At a high level, the main factors to consider in your dab surfaces are material type, mass distribution, surface area, and surface texture.

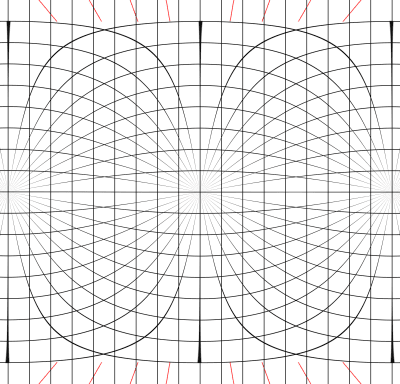

Thermal Expansion Of Boro Vs. Quartz

Metallic materials like titanium tend to heat up and cool down faster than crystalline materials such as borosilicate or quartz. Quartz is known to hold onto the heat for longer, making it the material of choice for those using a torch. Practically no one uses straight borosilicate glass anymore for a dab nail. Borosilicate breaks easily, making it very dangerous and un-economical. Most people quickly upgrade to quartz (if starting with a glass nail in the first place at all, since pure borosilicate nails are very rare to see these days). Quartz is much stronger than boro and is known to be able to take a much larger amount of thermal shock (temp changes).

Some are even brave enough to throw their hot quartz directly into the water just to prove the quality of the material in their nail. Others like to dip their quartz bangers in isopropyl alcohol after dabbing for a quick rinse. Try this with borosilicate, and you will likely be disappointed. Borosilicate can explode without touching any water at all, just from the thermal expansion of regular heating, let alone the thermal shock that a liquid plunge would subject it to.

Titanium vs. Quartz

Although titanium is much more durable than quartz for those who are accident-prone, most dabbers seem to have gravitated towards quartz over time. This is partially because titanium can be a little harder to clean.

The metallic surface also has different heat properties, which tend to bring more heat to the dab quicker than quartz. Some prefer the more aggressive heat, and some do not. Flavor is another consideration when choosing between quartz and Ti. The faster heat of titanium lends to a different flavor, and also tends to leave less material behind. Therefore, those who like to maximize their clouds may enjoy Titanium more as a dab surface. Those who live by the motto: “waste it to taste it”, may be more into quartz with it’s steadier heat dissipation and better heat retention for low temp dabs.

Ceramic (Nope!)

I have read about people that were happy with ceramic, but I’ve never met one. Personally I’ve tried plain ceramic a few times and each time the surface got irreparably “chazzed” after just one use. This adds a grimy perception on top of the fact that it actually tastes bad. The flavor was also not anywhere near what I expected. I will admit that I have only tried one or two different ceramic dab nails, but so far I’m not a fan. That being said, silicon carbide is actually technically a ceramic (even though it looks and feels more like a metal) and SiC is probably my favorite dab surface so far.

All about Silicon Carbide, Moissanite, and Obsidian…

In 1969, a large meteorite fell to earth near Murchison, Victoria, which led to the discovery that silicon carbide (SiC or CSi), while rarely found on Earth, is abundant in deep space. Meteorites striking the Earth from space remain the chief natural source of silicon carbide, typically called moissanite after the scientist who discovered it. So far we’ve theorized that moissanite originates in carbon-rich star systems and then travels here.

What a trip!

Don’t worry if you don’t have the time to wait for the next meteorite shower to hit Earth– we can synthesize silicon carbide via a thermal process which turns pre-ceramic polymer into the finished ceramic. It then becomes the silicon carbide (SiC) that we know and love. In the case of naturally discovered moissanite, the meteorite sourced material goes through a purification process before being thermally decomposed into the finished silicon carbide product.

SiC Functionality

Silicon carbide (SiC) was quickly found to be a useful material in the industry. A few applications that require the high-endurance properties of SiC include industrial refractory furnaces, car brakes, bullet-proof vests, high-quality drill bits, sharpening stones, grinding wheels, and sandpaper.

Silicon carbide is especially suited for applications that require surface hardness to be extremely high. It’s fairly tough as well, compared to other dab surfaces (see toughness vs. hardness), but its strength comes from its ability to resist abrasion, chemical reactions, and thermal shock. The physical properties are maximized for surface durability, making it the choice of many for a rugged and flavorful dab surface. Another property of SiC is that it heats up quickly and also transfers the heat more quickly than most other surfaces.

Is SiC The Same as Obsidian?

No, obsidian is not the same as silicon carbide. Obsidian has been used as a product name, which is not necessarily made from actual obsidian. One big difference between SiC and obsidian is that obsidian is made naturally here on Earth. It can be formed in volcanoes, while SiC is made naturally only out around orbits of very different stars than our own. That being said, some particular companies may have simply labeled silicon carbide as “obsidian” as a marketing technique. One such particular company does disclose that their “obsidian” is a proprietary material that they created and not the geological mineral. The latter is normally assumed, however, resulting in confusion.

What about corundums like ruby or sapphire?

Dabbing with Corundum (Ruby/Sapphire) vs. Carborundum (SiC)

Ruby, sapphire, and SiC share some similarities besides their similar names. They can all be synthetically produced for commercial availability. Both corundum and carborundum have amazing surface properties that allow for easier cleaning compared to quartz or titanium. They are also both right in that price range that gets you all of the glory of the best dabbing while being surprisingly affordable.

One main advantage of ruby over SiC is that you can see what needs to be cleaned a bit easier, since it is transparent. If you tend to get “OCD” about keeping your banger clean, this may be the one you are looking for to stay on top of it. It also just looks amazing. Who doesn’t like dabbing off precious gemstones? One huge disadvantage is that it can break much quicker than SiC. Careful procedures need to be adhered to in order to keep it intact.

Ruby Vs. Sapphire

Hardness does not equal Durability

What does this tell us about materials for dabbing?

Surface Area Factors and Modifiers

Besides the material type, the form and shape of the dabbing surface will make a difference as to how it will ultimately take on heat. The main factors here are width, mass distribution, and texture. These factors all change the amount of surface area and the distance from the heat to the dab. Dialing in these factors will help you find the sweet spot between flavor and maximum cloud production.

Dab Surface Area

The wider the area on the bottom of your dab nail, the more concentrate that will be exposed to the bottom surface at once. Compared to the side walls, the bottom surface is normally the hottest. This means if you place the dab on the side walls it might just dry out before it gets a chance to hit the right temperature. More frequent and serious dabbers will either want to stick with smaller dabs or use a larger surface area. 30mm seems to be the max surface area that any dabber will likely need. Even the most demanding concentrate connoisseurs normally don’t need more surface area. 25mm buckets are just right for most needs.

Advantage of going smaller (20mm)

Some prefer the compact and efficient air cavity of the smaller 20mm bangers. The dab mixes with less air. This leaves the dab untouched by extra oxidation, which preserves more cannabinoids and flavor. There is one other advantage to a smaller dab surface: less banger to clean. Taking that all into account, one disadvantage of 20mm is that you can’t just rely on any insert fitting inside. Most of the buckets made for a larger banger just won’t fit right, so pay attention to the outer diameter — especially if using a banger with thicker walls (see next paragraph).

Shape and distribution of mass

Besides the shape of the surface area, the distribution of mass in your nail also plays a role in how the heat is transferred. The different forms and shapes of each nail can play a surprisingly big difference in the overall experience. With bangers, the wall thickness is one variable to consider: typically from 1mm to 4mm thick. A thicker wall will take longer to heat, but also cool down slower.

Thicker bangers are mostly ideal for torch setups where good timing is important and you want to avoid heating it up quicker so as to avoid cracking. When glass heats unevenly, it also expands unevenly at a microscopic level. This causes some of the particles to push on each other, and if enough pressure builds up it can result in glass breakage.

Besides the wall thickness, there are also bangers which include a thick inner “core” which consists of a quartz cylinder that has been fused to the bottom dab surface. This inner core serves as extra storage of heat and serves a similar function as a thicker wall while taking less energy and time to heat up the entire banger.

Inserts

Terp buckets or inserts are one of the best ways to increase the surface area inside a quartz banger. There are a variety of sizes and materials on the market in 2019, such as quartz, SiC, ruby, and sapphire. The great thing about using an insert is that you can keep the bottom of your banger clean by using a terp bucket insert to shield it out. Just switch out the insert, and you have a fresh dab surface ready to go with a mostly clean banger.

If you make sure to get an insert with the right volume it will also help to reduce cleaning time since the only surface that touches concentrate is the very bottom and the bottom of the side walls. The surface area matters, and although slightly reduced with the bucket, there are definitely options that suit even the most hardcore dabbers. Along with thermal core bangers mentioned above, there are surface area modifiers that can increase the surface area within the insert itself (see below).

Pearls

Terp pearls (or beads) are another great way to increase the heated surface area and reduce cleaning. Large pearls also have the added advantage of raising the concentrate slightly above the heated dab surface, making some of the product heat indirectly from the heated surface. If you can get your pearls to spin it will help to distribute all of the concentrates across the hot surface more evenly and mix it up into the heated air. Besides that, it’s just a ton of fun! Check out the dedicated article for more information on how to spin pearls.

Dimpled bottom (opaque) vs flat (clear) banger

The question keeps coming up: What’s the difference between an opaque and a clear banger? Besides the way it looks, the opaque version almost always includes a different textured surface. While the clear banger is normally smooth, the opaque version normally has very tiny dimples on the surface that act as nucleation sites and effectively reduce the temperature needed to diffuse the extract.

The texture on an opaque bottom banger is ever so slightly dimpled, so it’s not as hard to clean as you may think. That being said, the significance of this texture difference is debatable. Some notice it, others hardly at all.

Nectar tip vs. bucket style

You can go as wide as a 30mm banger bucket, or down to as small as a 10mm nectar tip. The difference between a nectar tip and banger style nail is that the banger is going to have a much wider surface for the dab to sit. The heat is also applied more directly through a nectar tip to the dab since the heat can travel around the outside of the tip directly to a portion of the dab (without touching the coil).

However, nectar style nails and tips usually have their heat coils placed much closer to the actual dab surface, which is almost always titanium. For those gritty dabbers who prefer their dabs hot, a nectar style setup is perfect. The focused surface area, closer coil placement, and faster heat exchange of the metal surface all adds up to a quick blast into the ether. It’s also much easier to bring a nectar style nail up to a raging glow with the smaller mass and surface area.

Summary

SiC is the usually preferred material for the most optimal mix of function and value. Once you start going into the ruby and sapphire level, the advantages are smaller in proportion to the higher price tag. That being said, some just can’t live without experiencing the best, and that’s understandable. Right now it’s hard to imagine a material coming out that offers the same or better surface and thermal properties than silicon carbide at the same price point. But we could always find something new later.

For the majority of dabbers, generic quartz works just fine. It just takes a bit more cleaning in order to preserve flavor and promote heat transfer. For more heady dabbers, SiC offers most of the properties of ruby and sapphire, but without breaking the bank, or itself. For now, a silicon carbide insert inside a quartz banger is my go-to nail setup, although I am constantly experimenting. If you need a little more power, or are using a capper already, but don’t necessarily want to crank the temps, just throw in an insert and/or a few pearls to strike your ideal balance between flavor and volume!

Note that flavor and effect are also heavily influenced by other non-related factors such as using a capper tool, temperature control, and/or timing.

Was this informative? Have any tips?

We’re always looking for a good dab surface discussion! If you have anything to add feel free to reach out.