25mm Heat Coil Replacement

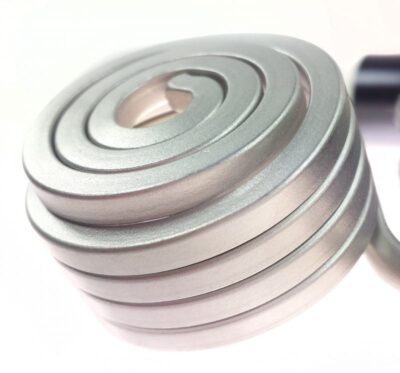

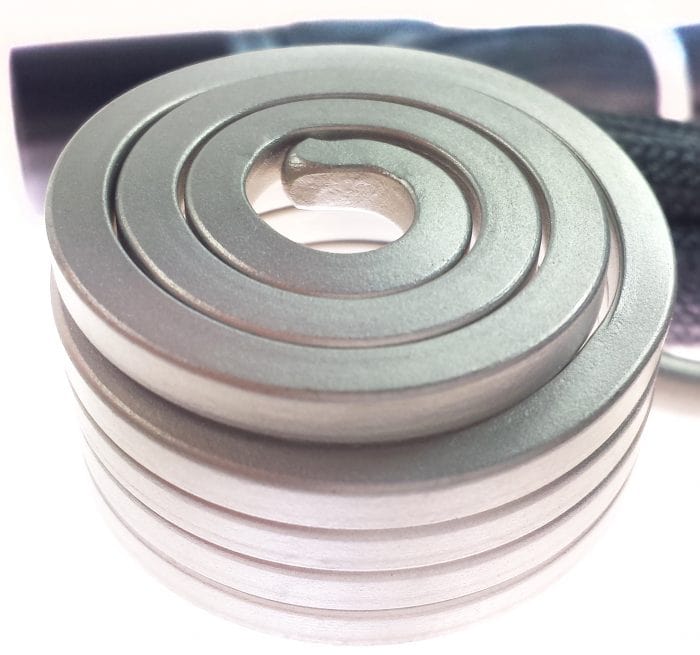

My 25mm heat coil replacement is reliable, accurate, and affordable. It has bottom wraps to heat the bottom of your banger for efficient heating. Wiring is compatible with many other controllers on the market but if you are unsure please get in contact and verify before purchase. I will be glad to help you find out what you need.

- 25mm heat coil

- Coil wraps around the bottom for additional bottom surface heating

- 100W/120V coil (USA standard)

- Durable Kevlar cord covering is rip and shear resistant

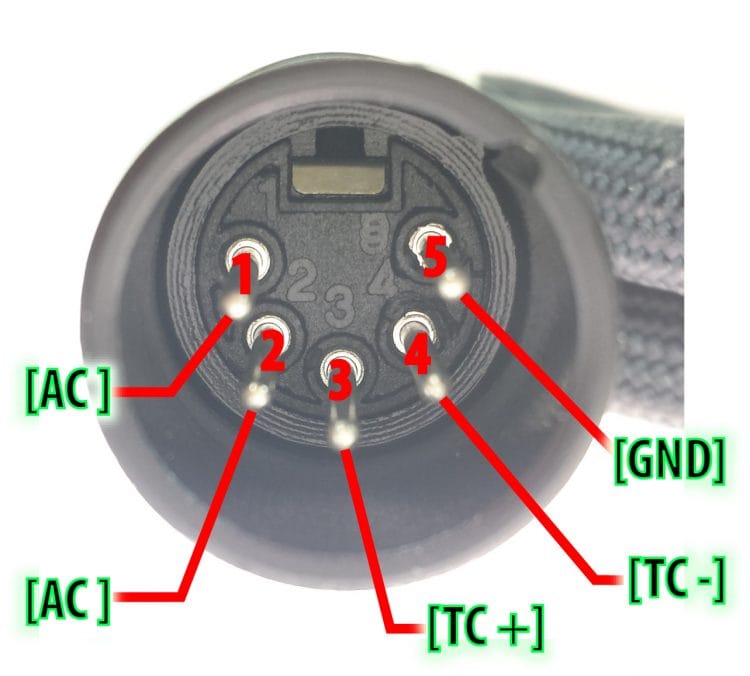

- XLR 5-pin connector

- Wiring order on plug (important): pin1=AC load, pin2=AC load, pin3=TC+, pin4=TC-, pin5=ground

Please be aware that some coils and controllers try to be proprietary and have wires that are switched around in a different order on the plugs. When the wiring order of the coil and controller do not match, malfunctions may occur. Read below on this page for more info. and if you are still unsure I can help you find out what you need.

$39.99

Coil Wiring Order Is Important!

Your e-nail and/or coil may malfunction dangerously if the wiring order is not confirmed to match! Please pay attention to add on options for coil wiring order to match your setup. Some controllers are wired differently (even though they look like they might match). It may look like the same size plug but some companies wire their enails differently to try to seem special and trick their customers into repeat replacement orders. Your e-nail will probably not work and likely even malfunction if it does not match!

How To Ensure Compatibility

Please first email the original controller or coil seller for the wiring order on your gear. Many sellers are responsive when you ask them. Just ask what the wiring configuration is on the 5-pin XLR plug. That’s all! When you find it, please make sure it matches the listed configuration listed on this page (or select the custom wiring option). If for some reason you cannot get a response please check out the heat coil wiring guide for quick and easy instructions to find out what the wiring order is on your gear.

I Am Here To Help

If you are still unsure after reading the guide, I can help you out with any additional questions or concerns. You’ll definitely want to make sure you are ordering compatible gear to make sure the setup will actually work and to avoid throwing away time and money. If you do not know for sure how your e-nail or coil is wired, it is your responsibility to find out. Returns may not be accepted due to incompatible wiring.

Questions Always Welcome

If you have any questions please don’t hesitate to use the contact page and send a quick message. Here is a heat coil plug wiring guide, which is essential if you want to match different brands. If you are looking for more information specifically about which enail accessories check out the dab gear accessories guide to see what’s all involved in a full setup and starting at full potential.

Banger Safety

A hose clamp is probably the most secure option to hold your banger up to your heat coil. Other options such as the bands are also very secure, but may not hold well onto bangers with certain neck shapes. The clamp below the bucket ensures that you always have a tight coil fit on the bottom of the bucket.

Conner Goertzen

I am a DIY electronics enthusiast who has been 3D printing since 2018, making custom e-nail controllers since 2016, and putting together custom electronic instruments since 2011.